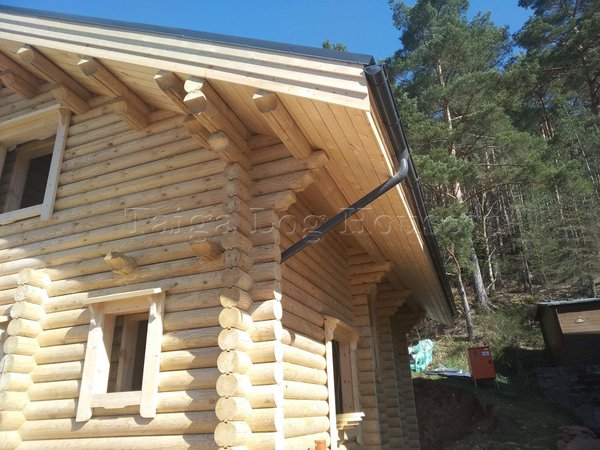

Log houses with high heat insulation and double outside walls

Taiga offers to our customers totally new technological solutions for heat insulation of log houses - double outside walls and a special windproof longitudinal “tongue-and-groove” joint. This allow to build an ecologically friendly house from solid wood with a heat insulation value of

Uwerte = 0.13 W/(m²·K).

To understand the effect of this technological solution:

such value of warm insulation corresponds to a solid wood wall that is more than 100 cm thick (more than one metre!).

A house with double outer walls means - a log house inside another log house (house inside the house)

It is well known that solid wooden houses (log houses) are a natural, ecological product and for this reason they are so popular all over the world. However, log houses have significant disadvantages:

a) Log walls have a relative low heat insulation value - Uwerte = 0.35-0.60 W/(m²·K); when the limit value according to current European standards is U < 0.25 W/(m²·K), and a house with high heat insulation according to the Passive House Standard has a U < 0.15 W/(m²·K).

b) The second problem is the poor wind protection of simple “moon” longitudinal log joints in house walls.

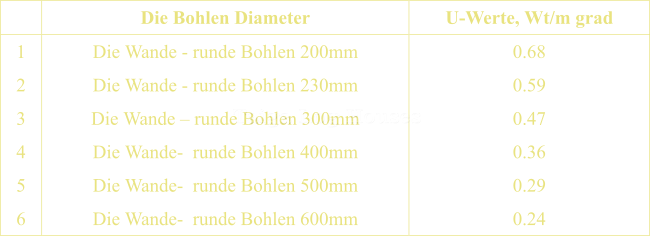

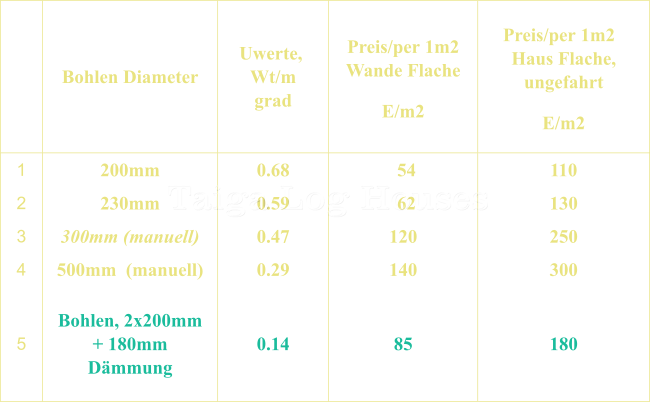

Now let consider the table with the calculated U-werte for walls made of round logs of 200-600 mm diameter, which are commonly used for log houses construction.

It can be seen from the table that none of the log diameters of 200-500 mm meet the new strict European standards of house insulation. And only logs larger than 600 mm in diameter (logs with a diameter never used by homebuilders) have a heat insulation value of U = 0.24 W/(m²·K). Therefore, only logs with a diameter of 60 cm meet the new E-standards. However, the wind protection (!) of such walls remains a serious problem, making it impossible to achieve the required heat insulation value.

Therefore, the second problem is the poor wind protection of the simple longitudinal grooves of the logs. Even if the houses are built from very thick logs of 60 cm diameter, the heat insulation problem is not solved, and additional wind protection is required. Because of these problems log houses need to be additionally insulated with artificial building materials (mineral wool), protected with wind protection foil, and covered with wooden boards from the inside. All this is doubly difficult to do, as a log house "shrinks" (is setting down) after assembly and the whole system of additional heat insulation has to slide.

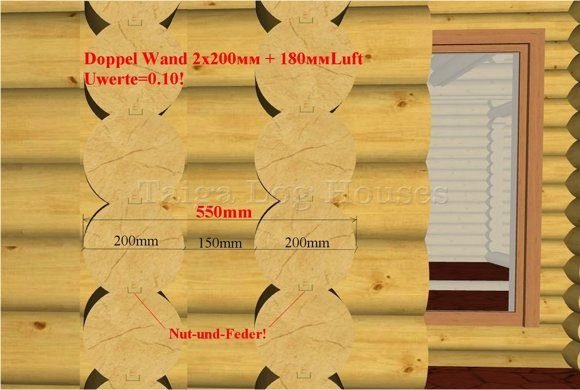

We offer conceptually new solutions to our customers – log houses with double external walls and special windproof longitudinal profile of log joints. The sort of houses is built in usual logs with diameter 200 mm, internal walls are ordinary (single), and external walls consist of two parallel walls, each of them is 200 mm thick. There is air or heat insulation with thickness 180 mm between them.

In fact, external walls are similar to a modern glas-packet, where glasses are two walls (each of them is 200 mm) with 150–200 mm of air or heat insulation between them. The U-value of such systems is: U-werte = 0.13 W/(m²·K).

The unit “log 200 mm - 180 mm thick heat insulation - log 200 mm” has perfect heat-insulating properties with Uwerte = 0.13 W/(m²-K).

The second important technological solution is the complicated profile of the longitudinal jointing of the logs - moon+tongue and groove joint.

As we have already mentioned, a “moon” longitudinal groove, which is used by the majority of manufactures of log houses, cannot be a proper wind-sheltering. A simple groove is easily blown through. We offer logs with a complex profile - "moonlight" groove + “tongue-and-groove” joint. The photo of our log clearly demonstrates it. We borrowed that system from the Sweden. The manufacturer of our equipment and technology is a Swedish company, named Stenlund.

So, insulating material between logs (natural) is placed not in an simple “moon” arc, but in a complex “tongue-and-groove” profile between logs. The sort of log joints becomes practically impossible to be blown through by wind. If air passes through one wall somewhere in angle joints, it will appear in the buffer area between two walls and meet one more wall on its way to the house - the second wall with exactly the same complex longitudinal joint.

But if the space between the logs is filled (foamed) with modern ecological insulators, the air passage through such a system becomes impossible (is at the level of a breathing log house).

An important disadvantage of houses made of thick logs with diameter 50–60 cm is the fact that they are generally built in spruce. Spruce is a fast-growing wood material, it has little pitch (pitch protects wood against humidity and decay). Finnish, Russian and other manufactures of log houses do not use spruce in house walls building, but pine only. But slowly growing northern pine with a diameter of 50-60 cm is a rarity in the forest, so builders of hand-timbered log cabins from thick logs often use spruce. Inexperienced customers don't realise they're being cheated. We build our houses only in pine-wood! It is essential for life durability of a house.

Finally, one of the most important advantages of our houses with double outside walls with tongue and groove log profile is their lower price. With heat insulation, which is 2.5 times higher than the one 430–500 mm thick walls have, and much higher wind-sheltering "tongue and groove"of log joints, the house has a lower price – 1.5–2.0 times cheaper than the price offered by the competitor. In fact, only external walls are built double, all internal walls will be usual, single – 200 mm.

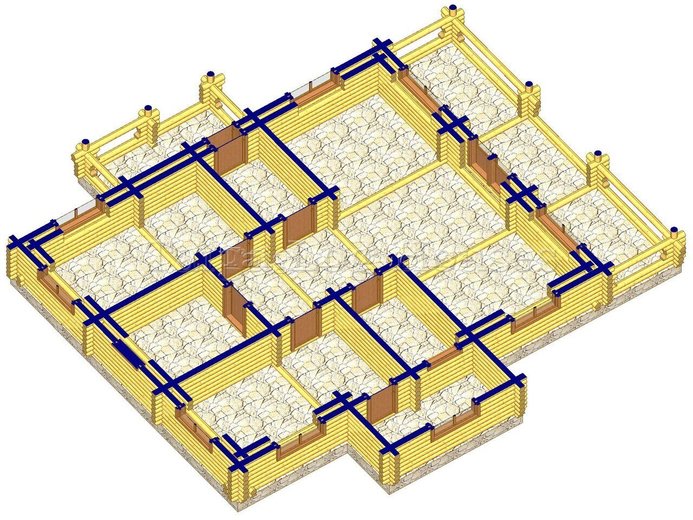

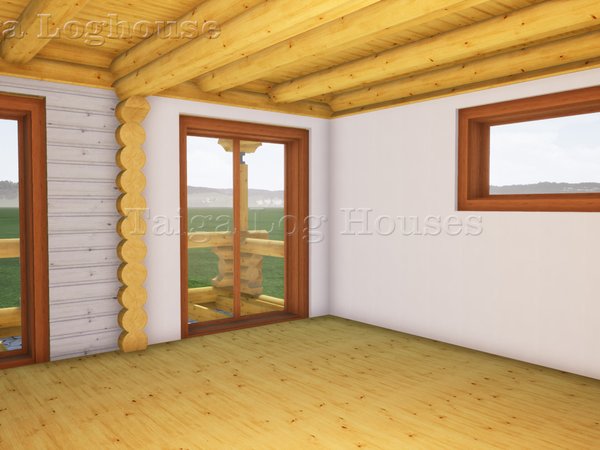

What does it look like?

Look at a design of such a house made for Germany:

Assembling such houses is also much cheaper. Each single dry piece weighs 5-7 times less than a competitor's hand-built house pieses , i.e. no crane is needed for assembly, and the assembly process itself is not as heavy or expensive.

The advantages of our double outside wall system are the following:

1) Perfect heat insulation, Uwerte=0.13 (it is less than EU Passivhaus-Standart, U<0.15);

2) Proper wind-sheltering systems consisting of two walls with a longitudinal log joint profile “tongue and groove”;

3) Our houses are built only in pine-wood, while our competitors (thick log cabins) use thick spruce, which is in fact a lower quality timber;

4) The exterior and interior natural design of log houses will be preserved;

5) Construction strength of double external walls is increased

6) The houses have a relatively low price.

Double walls 550 mm + insulated roof 300 mm

Our company is constantly working on innovations in construction and insulation. Therefore, in addition to this unique solution for log houses, such as double walls, we have developed an alternative, simpler and cheaper technology for insulating outside walls - the sliding warm insulation method.

How do I order a log house from our company?

Contact us and we will build for you a log house with high level of warm insulation which meets the requirements of the strictest European standards.

Nos contacts en Turquie:

► Région de Marmara

- M. Hikmet Karadeniz (Istanbul)

téléphone: +905335713698

e-mail: hikmetkaradeniz@mail.ru

► Région d'Antalya

- M. İsmail Aslan (Antalya)

téléphone: +905337770990

e-mail: liamsinalsa@icloud.com

► Région orientale de la mer Noire

- M. Ümi̇t Doğan Vayi̇c (Hopa)

téléphone: +905435430548

e-mail: umit@vayicgumrukleme.com, info@vayicgumrukleme.com

Nos contacts en Allemagne:

► Rhénanie du Nord-Westphalie, Rhénanie-Palatinat (partie nord), Hesse (partie nord), Basse-Saxe, Saxe-Anhalt, Thuringe et autres

- M. Udo Theis,

e-mail: utheis@udotheis.de

téléphone: 0152 29 539 274.

► Hesse (partie sud), Rhénanie-Phalsbourg (partie sud), Sarre et Bade-Wurtenberg

- M. Donald van der Laan,

e-mail: dondvdlaan@gmail.com

téléphone: 0152 15 178 988

► Bayer

- Mme Eva Wissman, Spécialiste Certifié du Bois

e-mail: e.wiesmann@taigaloghomes.de

téléphone: 0800 723 8775

Nos contacts en Autriche:

► Tyrol, Salzbourg, Haute-Autriche, Basse-Autriche

- M. Walter Morier

e-mail: walter.moriel@chello.at

téléphone: +43-680-2334279

téléphone: +43-5332-93595

Nos contacts en Russie:

M. Semyon Dimitriev (en russe, anglais, allemand, bulgare)

téléphone: +7-911-230-31-72 (Whatsapp, Viber, Telegram)

e-mail: info@taiga-loghouse.ru

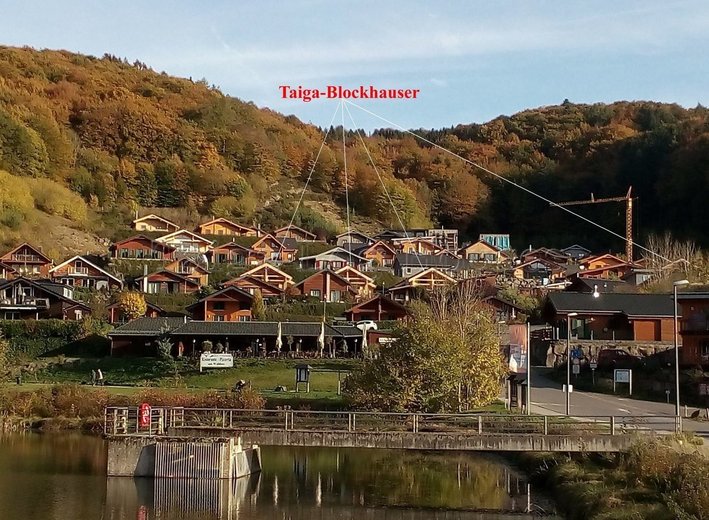

Where can you see our houses in Germany?

A great place to see our houses ist Riden-am-Waldsee - easily accessible from the three lands – from North Rhine-Westphalia, Rhineland-Phalz and Hessen - are all within 200 km of Waldsee.